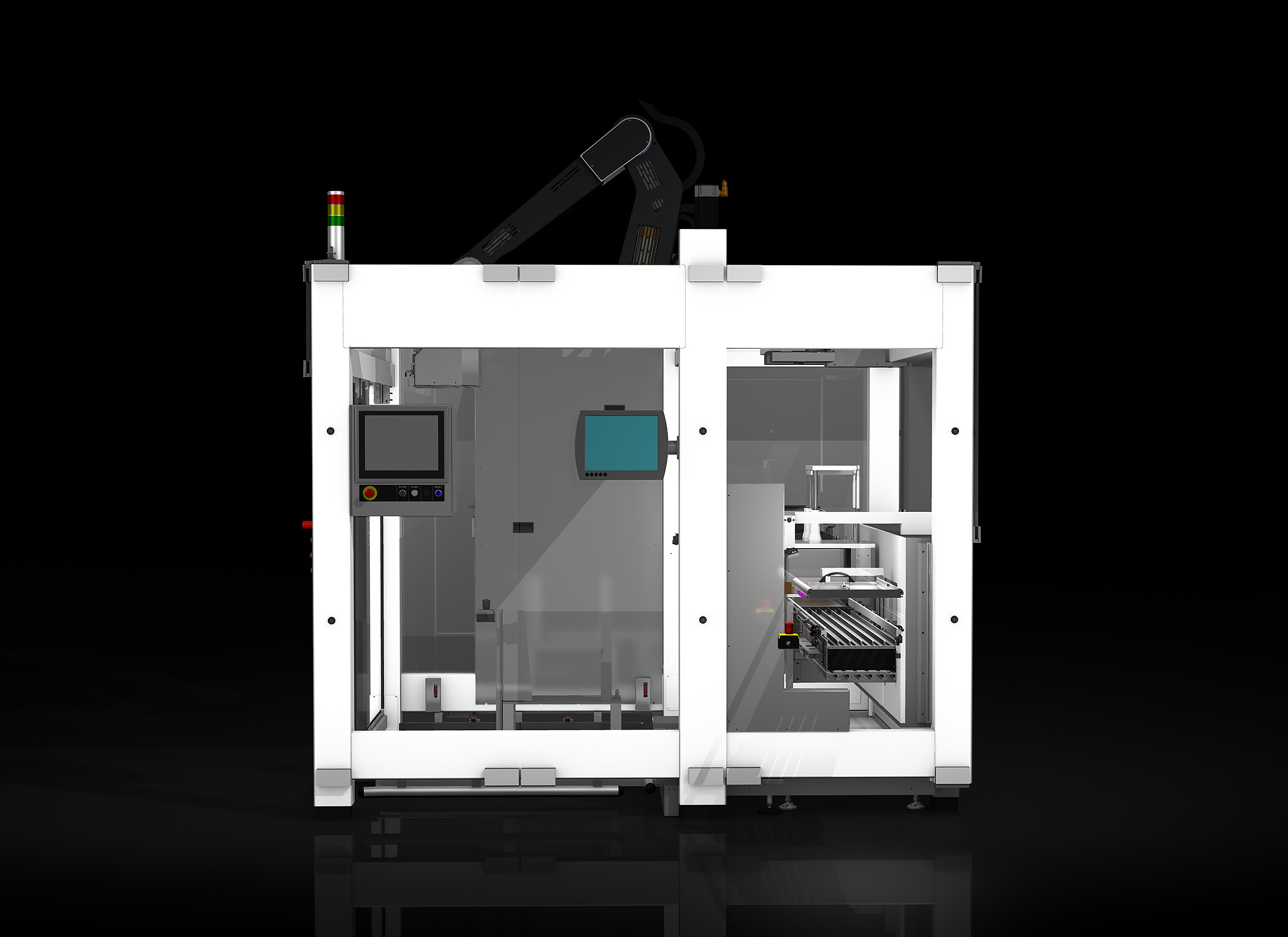

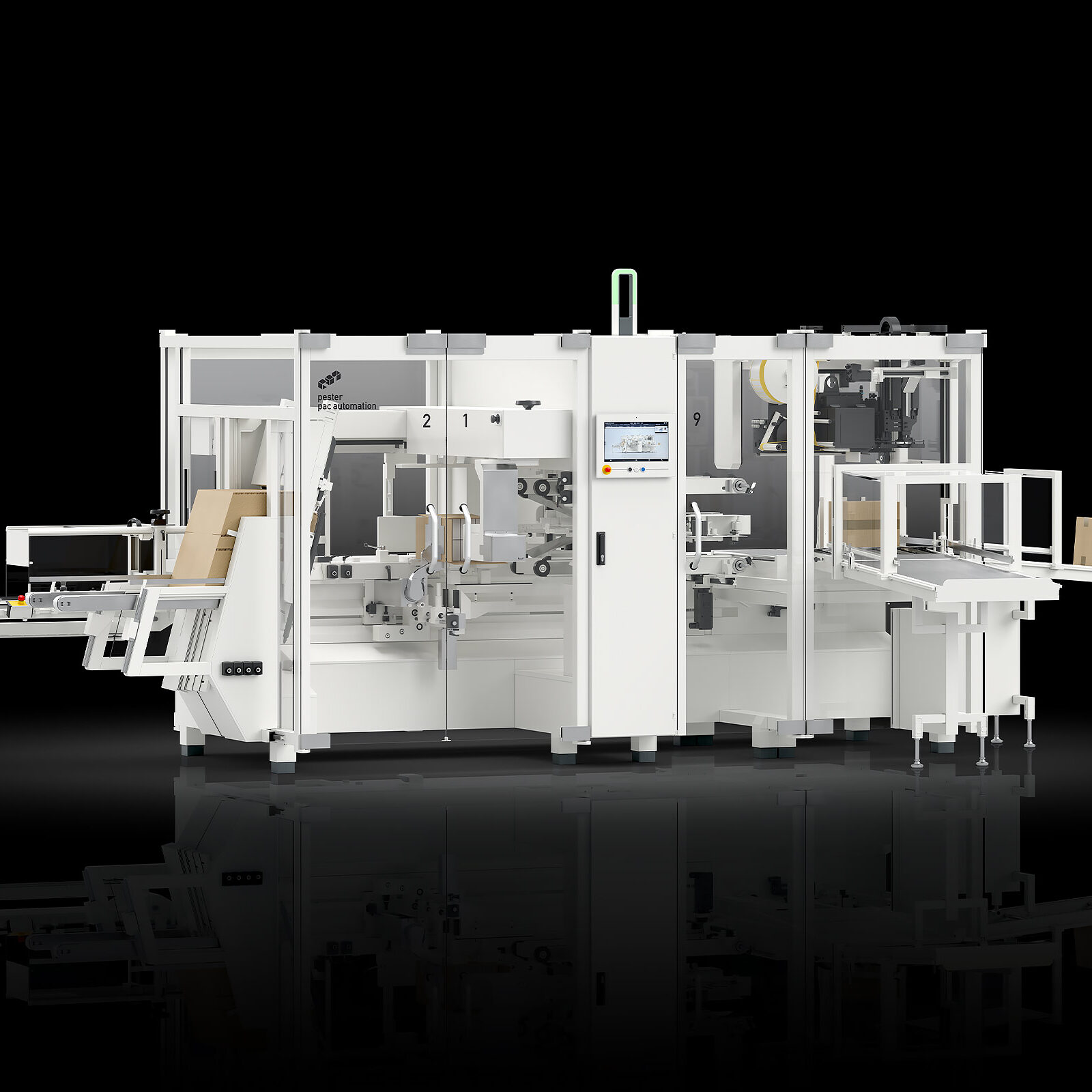

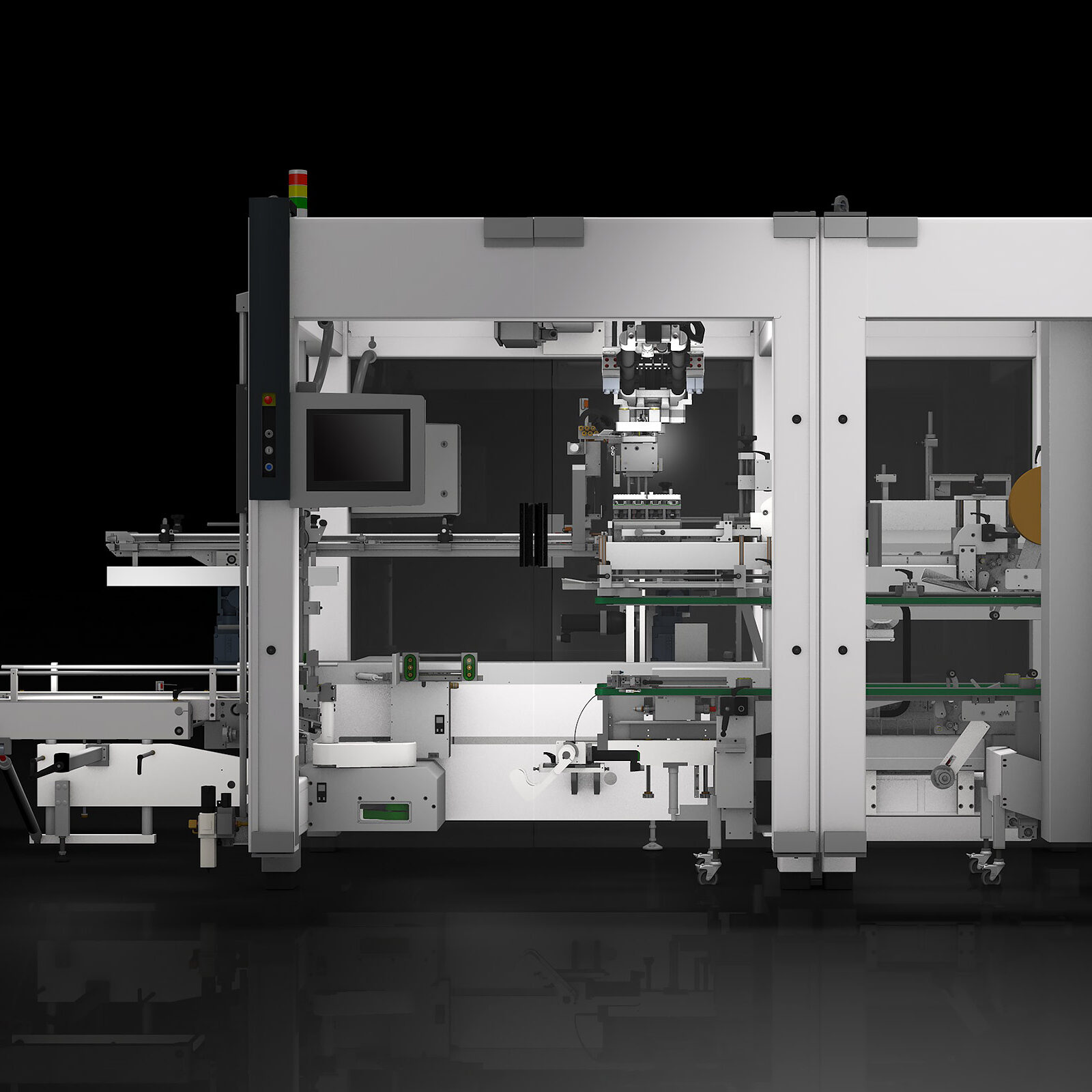

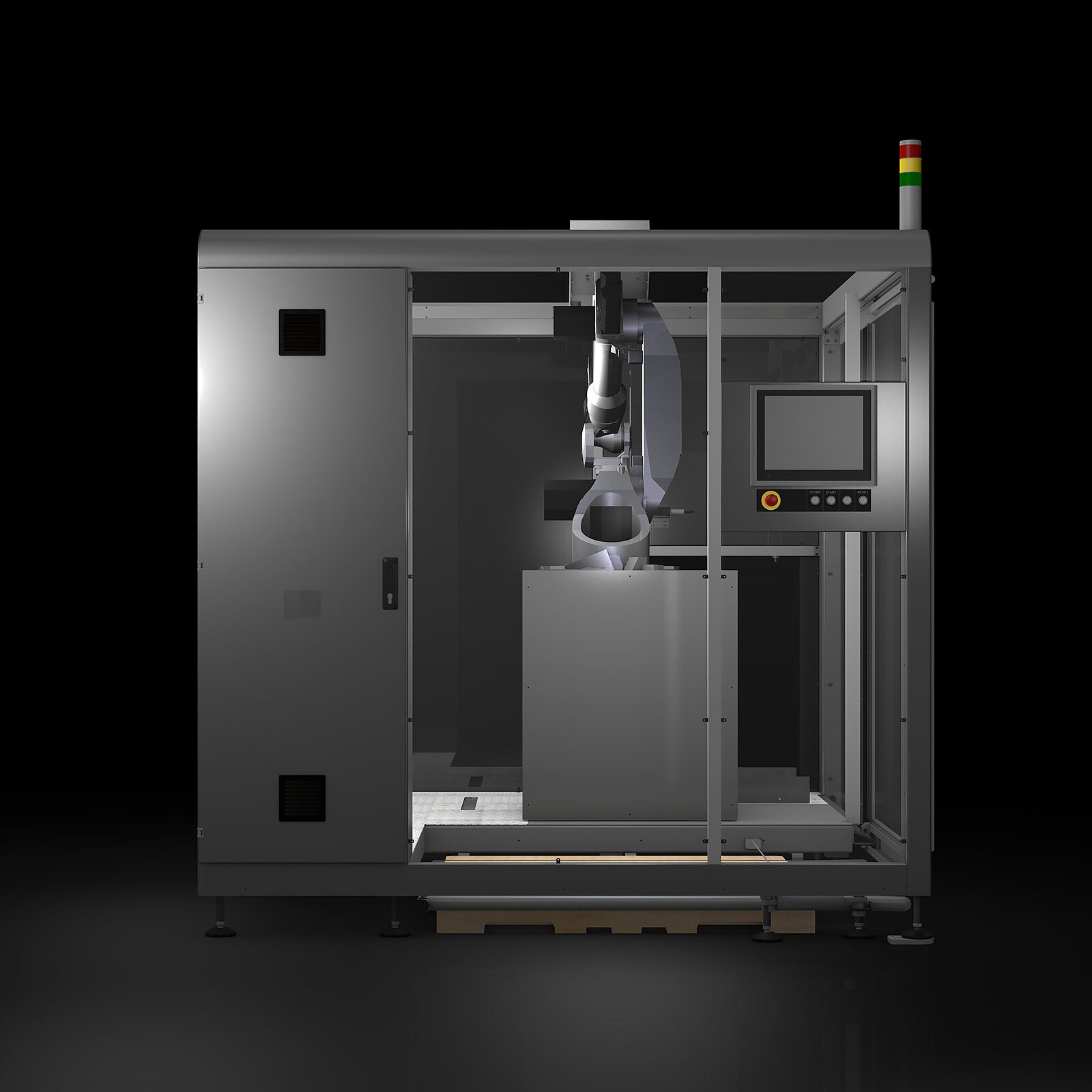

Rely on intelligent automation for your pharma line. New, fully automated depalletizing generation. It has high-precision handling with innovative gripper technology for vials, ampoules, inhalers and auto-injectors. Reliable position detection via camera systems integrated into the robot ensures the exact feeding of your pharma products, to the filling and packaging line.

Benefits

- Fully automated depalletizing, product handling and palletizing

- High-precision handling of pharmaceuticals

- Innovative gripper technology

- Reliable position detection via camera system

- Robotics: pester pac robot P 15

- Efficient – constant operation even during pallet change

- Pharma-proof – via modern labeling and monitoring systems

- Compact, modular architecture in GMP design

- Simple, reproducible format changeover in less than 10 minutes

Format range subject to feeding and collating system and features of machine.

| Machine dimensions | 2870 x 3080 x 3250 mm [L x W x H] |

| Ceiling height | 3250 mm to allow for operating range of robot |

| Features | 2 pallet stations |

| Robot | pac robot P 15 |

| No. of robot axes | 5 |

| Min. format range | case 230 x 230 x 90 mm [L x W x H] |

| Max. format range | case 600 x 400 x 400 mm [L x W x H] |

| Performance | up to 6 cases or trays/min. / up to 350 vials/ min. |

| Control system | Schneider Electric PacDrive 3 / Rockwell Automation (Allen-Bradley) |

| Pallet size | 1200 x 800 mm – 1220 x 1016 mm (48″ x 40″) |

| Max. palletizing height | 1400 mm (including pallet) |