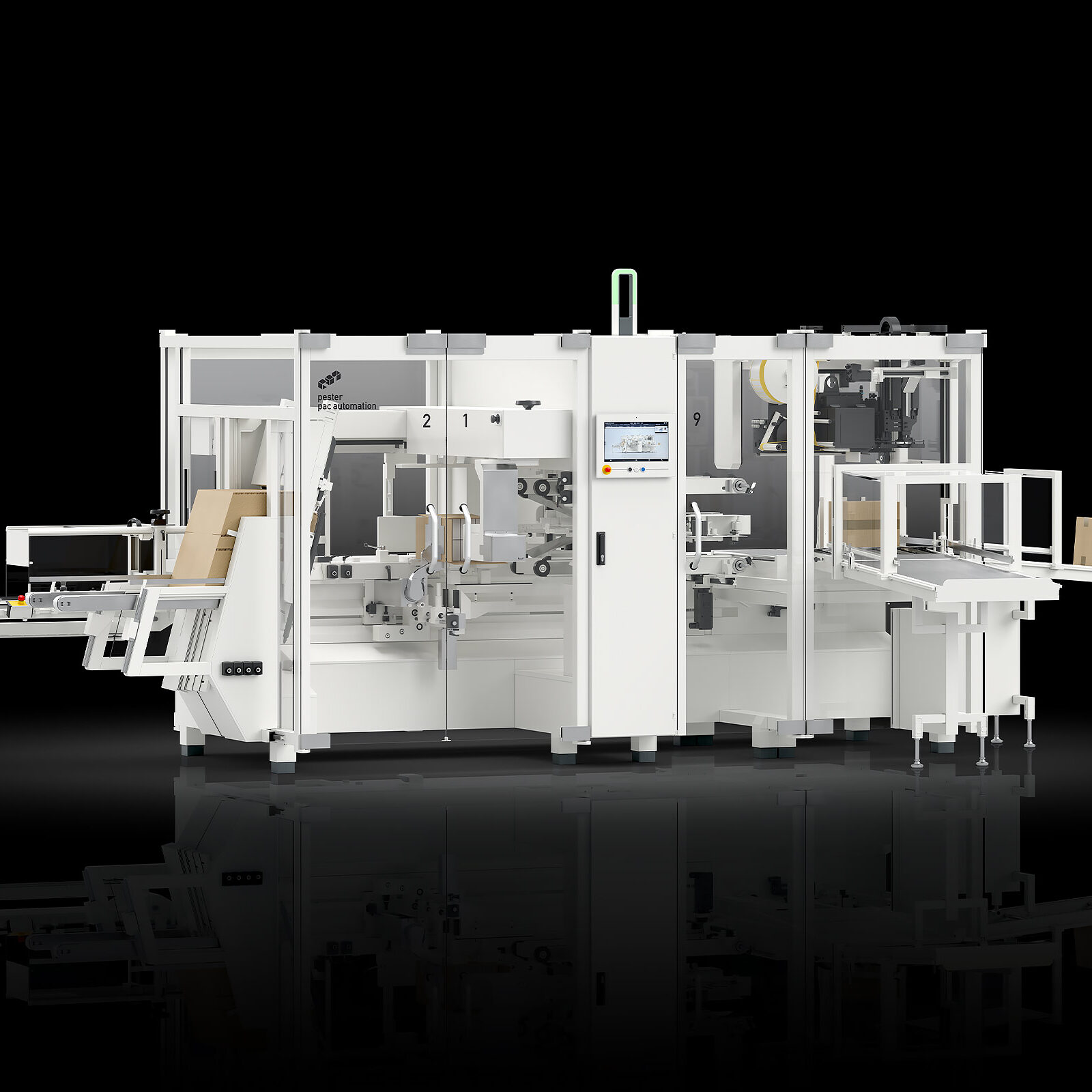

Do you associate success with versatile and safe packaging for your pharma folding cartons and bottles? Experience our shrink wrapper with its sustainable cutting-edge sealing technology for ultimate cycle rates.

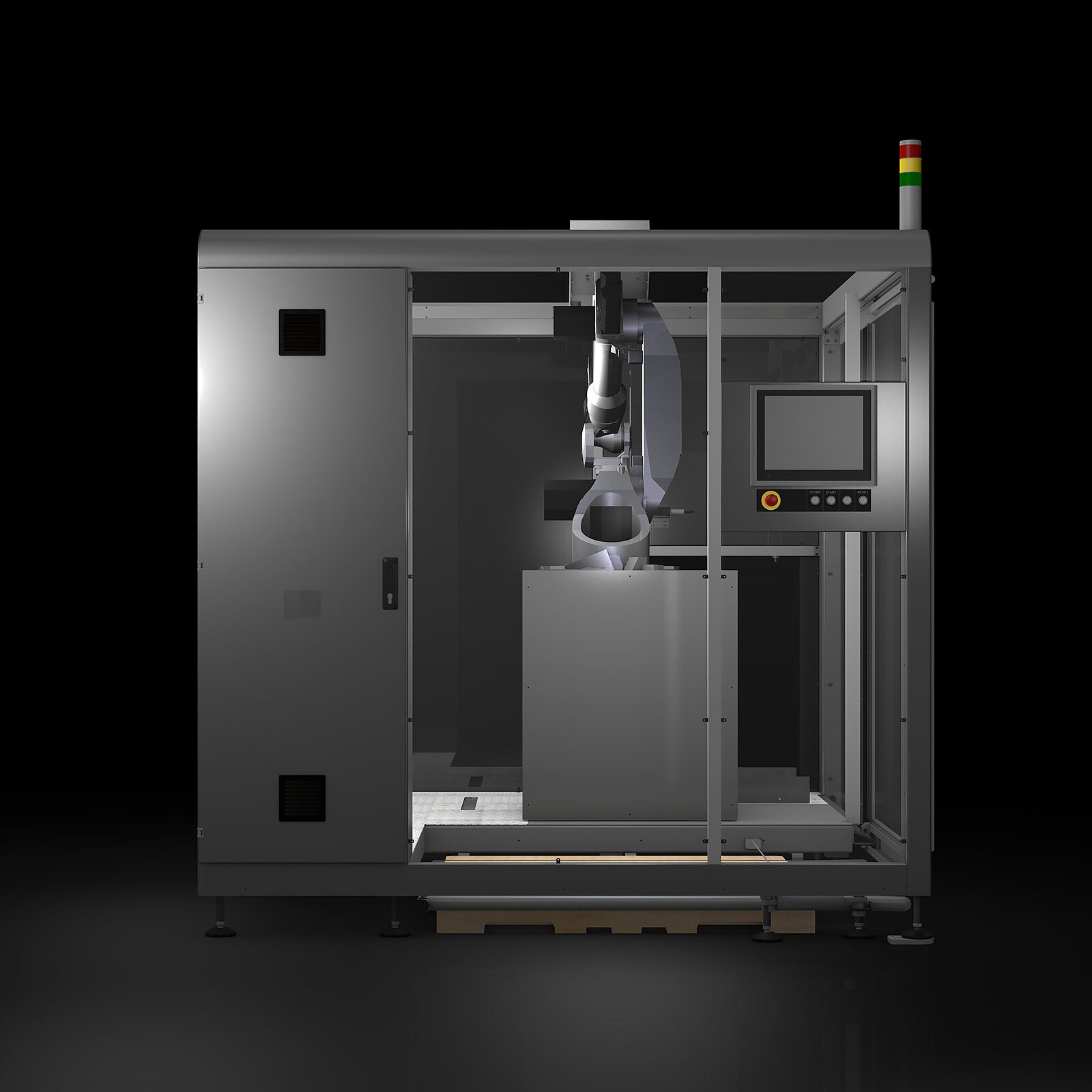

The transparent shrink tunnel demonstrates supreme excellent product safety for your pharmaceuticals and operating personnel needs.

Benefits

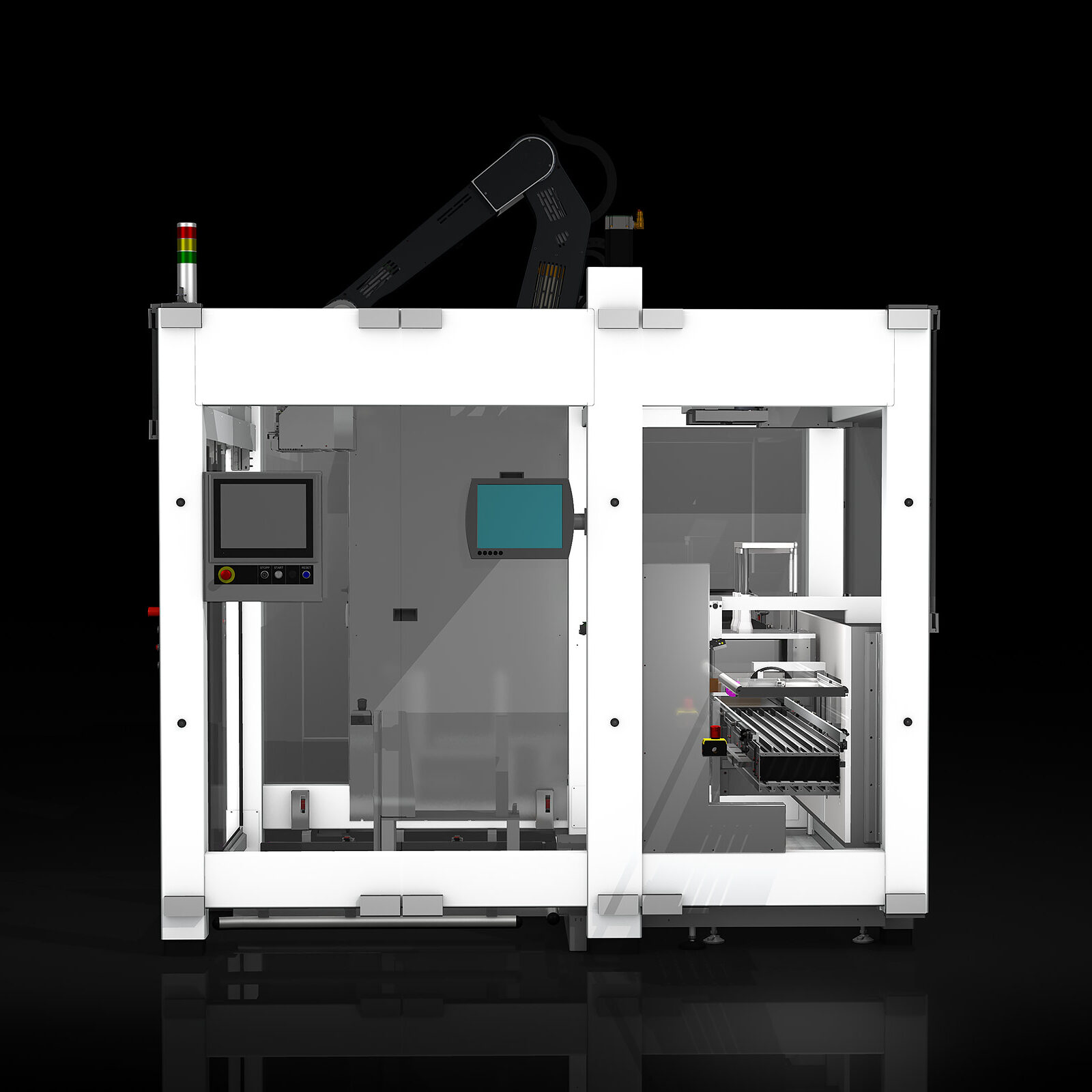

- New generation of human-machine communication

- Interactive 3-D visualization

Intuitive machine operation via 15“ multi-touch display - Doors made of safety glass with soft closing function: durable, antistatic, scratch-proof

- Transparent control cabinet

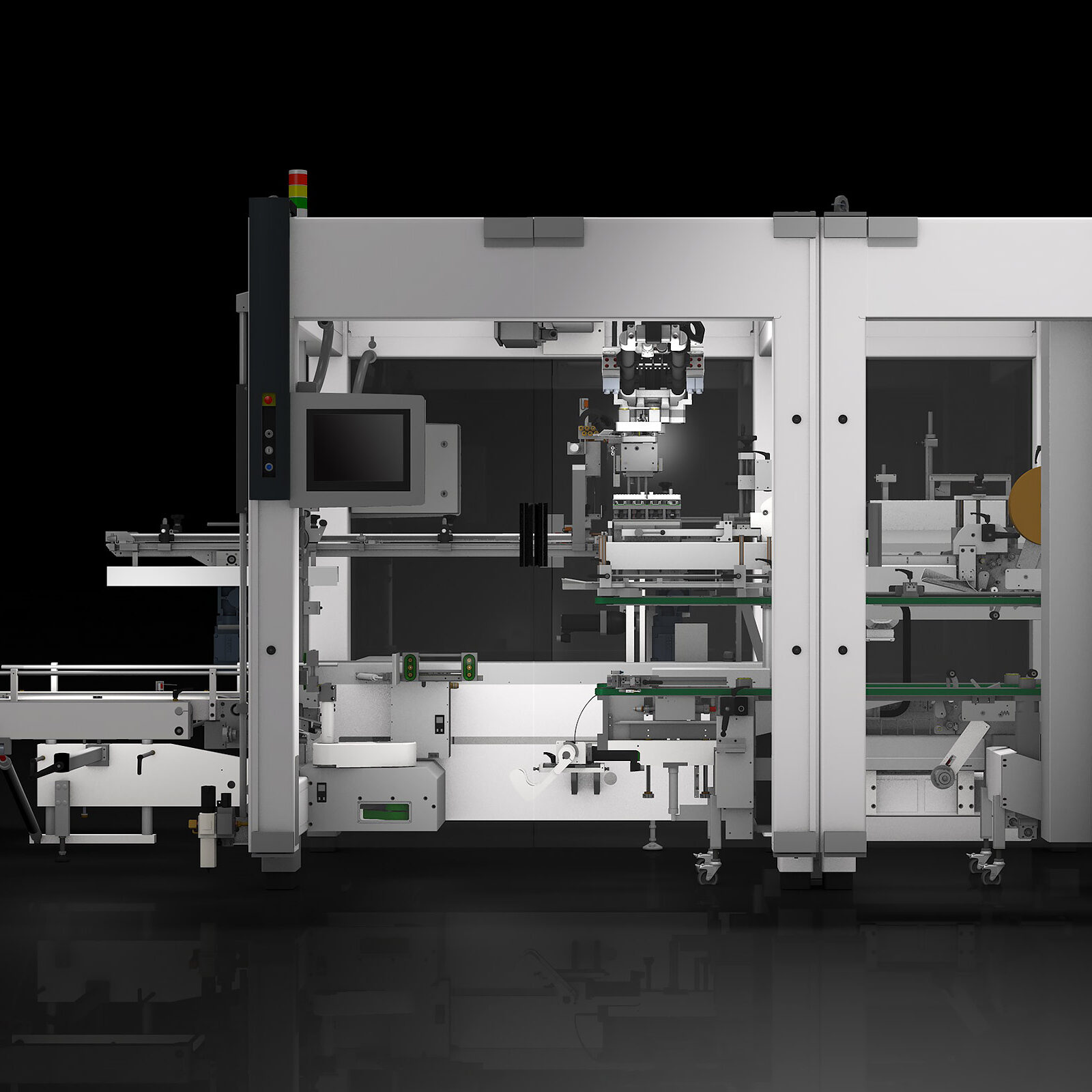

- Patented splicer – fully automatic film reel changeover without machine downtime

- High-speed machine performance with low life-cycle costs

- Compact, ergonomic, GMP-compatible machine design

- Multifarious collation configurations for folding cartons, pharmaceutical bottles and vials

- Quick and easy tool-less format changeover

- Flexible collating possibilities

- Ultimate pharma safety – controlled shrinking that is gentle on the product

| Machine dimensions | 4000 x 1680 x 2150 mm [L x W x H] |

| Features | inline feeding system, shrink tunnel |

| Min. format range | product 30 x 30 x 60 mm [L x W x H] collation 30 x 60 x 60 mm [L x W x H] |

| Max. format range | product 100 x 100 x 250 mm [L x W x H] collation 300 x 380 x 250 mm [L x W x H] |

| Performance | up to 50 bundles/min. |

| Control system | Schneider Electric PacDrive 3 // Rockwell Automation (Allen-Bradley) |